Mixing tank

Custom Made 50L- 30,000L Mixing tank

A mixing tank is essential equipment in many industries, including the food and beverage, pharmaceutical, and chemical industries. Mixing tanks are used to mix liquids and solids and can be either batch or continuous. Batch mixing tanks are typically used for small-scale operations, while continuous mixing tanks are used for large-scale operations.

Are You Looking for A Reliable Supplier of distillery equipment??

Feel free to contact us with product questions or to request support at any time; we'd be happy to assist.

Didn't find the right product or want some suggestions? Please contact us right away!

Mixing tank Structure

Regarding the structure, stainless steel mixing tanks typically fall into three categories:

- Single layer:the inner layer: adapts stainless steel plate SS304 or 316L material, and the surface mirror polishing.

- Double jacket:the jacket: made of SS304 steel, spiral jacket device, cold water from the bottom up without pressure, to achieve the purpose of the best heating and cooling.

- Three layers:the external insulation layer: the environmental polyurethane foam casting/ per lite particles, maintaining the temperature difference with the outside, to the effect of insulation.

- * Flat Bottom: Flat-bottom tanks have a prevalent and valuable design. Neutral geometry, which works well with solids or liquids, and a lower manufacturing cost, are benefits of flat bottom mixing tanks. Drainage is the only disadvantage, especially with solids and significant-viscosity liquids.

- * Dished Bottoms: Often used in pressurized tanks, dished bottoms are manufactured in three different geometries: 2:1 Elliptical, ASME 80:10 and Standard Flange and Dished. Dished bottoms offer increased rigidity, better drainage than Flat Bottoms, and better solids' suspension than cone designs - except for the 2:1 Elliptical design. But a longer shaft will be needed, increasing cost, and a special kicker impeller may be needed for the 2:1 Ellipticals.

- * Sloped Bottom: Sloped-bottom tanks provide excellent drainage without the need for a longer impeller shaft. However, solids suspension performance is reduced as the slope increases. * Cone Bottom: Cone-bottom stainless steel mixing tanks provide superior drainage, critical for high solids content slurries. Solids suspension, however, should NOT be done in a cone-bottom mixing tank due to fluid stall and stratification potential. Radial flow and temperature gradients can also be negatively affected.

- Tillable

- Integrated control panel

- Agitators

- Heated (Dimple, Half pipe)

- Cooled (Dimple, Half pipe)

- Load cells

- Level Switches

- Cleaning connections

- Skid mounted

- Several finishing levels

- Several materials (304, 316L, Duplex)

- *Gate agitator

- *Anchor agitator

- *Scraping agitator

- *Propeller agitator

- *Bottom driven agitator

- *Dispersing disk

- *Rotor/stator

- *Screw agitator

- *Combination of agitators

- *High-shear mixer

- *Turbo mixer

- *Side entry agitator

- *Static mixer

- *External homogenizer ...

- Bottom magnetic agitator with propeller impeller, speed from 50-400rpm or 50-800rpm. This agitator mixes thin viscosity, such as eye drops, injection, CIP liquid, water, etc.

- Top mechanical agitator with propeller impeller, the speed at fixed 71rpm or adjustable 20-200rpm or special requirement. This agitator mixes syrup, injection, blood, oral liquid, culture media, etc.

- Top mechanical agitator with anchor or frame impeller, speed is from 10-70rpm. It mixes higher viscosity, such as sediment or viscosity, oral liquid, etc.

- Top emulsification homogenizer, speed max 2900rpm for a small vessel, 1480rpm for a bigger tank. This agitator mixes the highest viscosity, such as suspension, oil, fat emulsification, etc.

- Bottom emulsification homogenizer, speed max 2900rpm for small vessel, 1480rpm for a bigger tank. This agitator mixes the highest viscosity, such as suspension, oil, fat emulsification, etc.

Mixing tanks technical parameter

We understand that every mixing tank is different. Therefor, we design our kettles tailor-made for you, so you can be sure that the tank will suit to your product and process best.

|

Materials

|

SS304/SS316L

|

|

Jacket: full jacket, dimple jacket, coil tube

|

|

|

Insulation layer: PU / rock wool

|

|

|

as to the thickness, we can make it according to your requirement.

|

|

|

Description:

|

Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosmetics and pharmaceutical

industries |

|

Heating mouthed:

|

By electricity (oils or water), by steam, circulation heating (hot water or oil)

|

|

Configuration:

|

1.manhole

|

|

2.CIP spraying ball

|

|

|

3.adjusting feet

|

|

|

4.sight glass

|

|

|

5.temperature gauge

|

|

|

6.pressure gauge / vacuum gauge

|

|

|

7.breather

|

|

|

Capacity:

|

50L-30,000L

|

|

Mixer Type:

|

Homogenizer or Agitator (anchor, frame, stirrer with side scraper, blade, impeller)

|

|

Mechanical seal:

|

SIC/SIC/EP DM (Standard)

|

|

Agitator power:

|

0.55kw -75KW

|

|

Sealing option:

|

Sanitary single mechanical seal/Double mechanical seal with cooling system

|

|

Voltage:

|

220V -480V

|

|

Motor:

|

ABB, SIEMENS, SEW, Domestic

|

|

Surface treatment:

|

Inner polished and outside polished

|

|

Available connection:

|

Clamp, Thread Butt weld, Flange

|

|

Application scope:

|

Dairy, food, beverage, pharmacy, cosmetic, etc

|

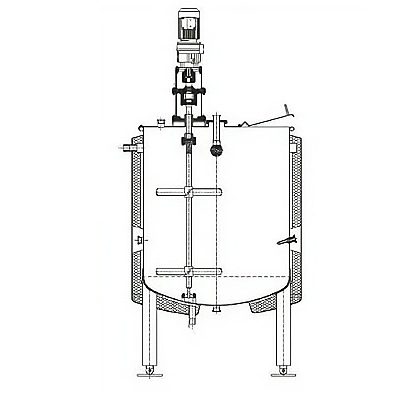

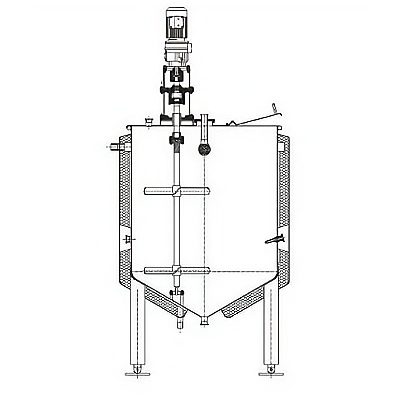

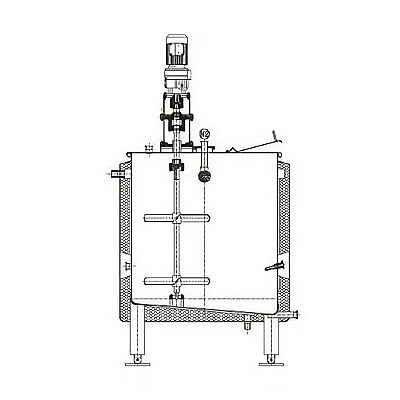

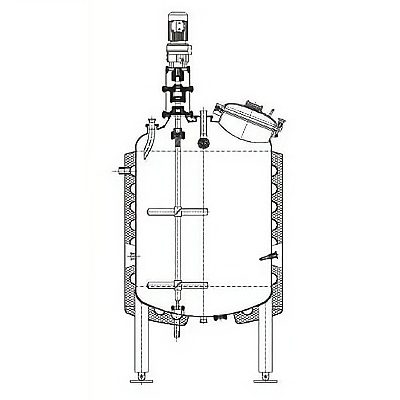

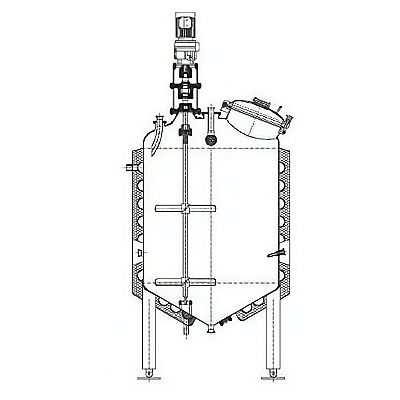

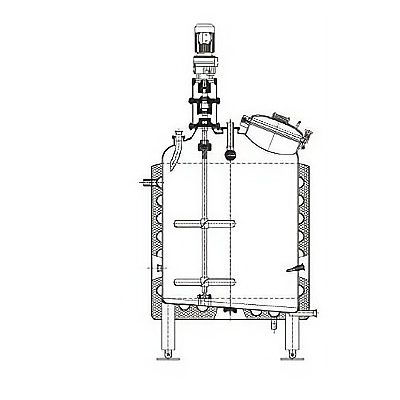

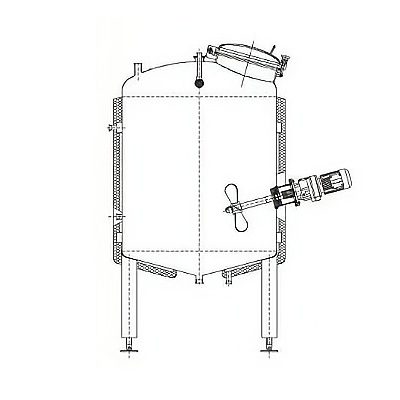

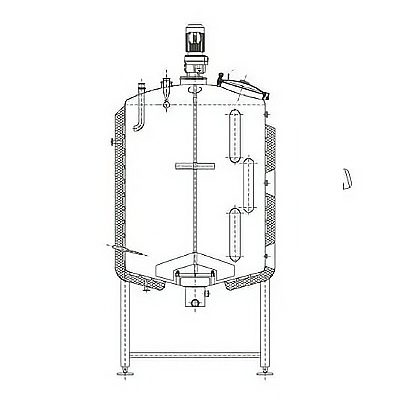

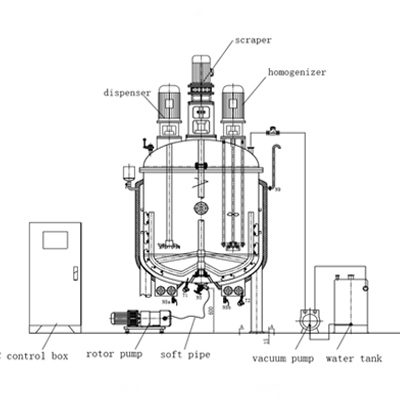

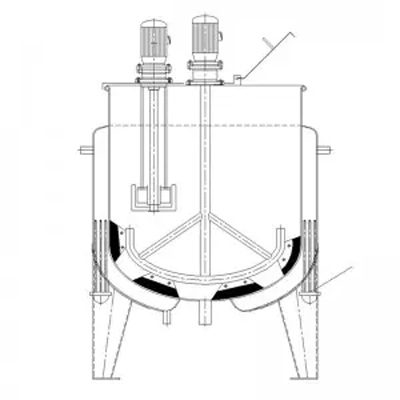

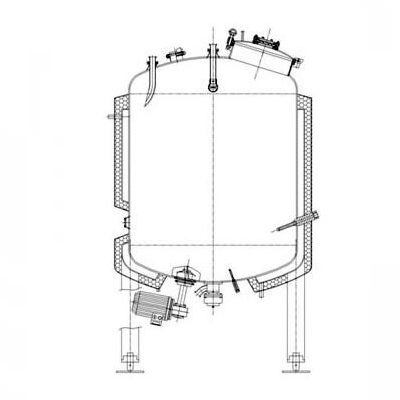

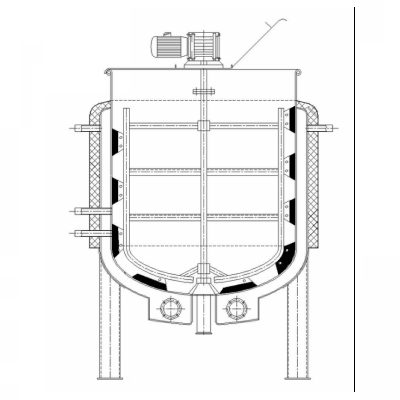

Drawing of mixing tank

Jacketed Dish-bottom Mixing Tank with Hinged lid

Jacketed Conical-bottom Mixing Tankwith Hinged Lid

Jacketed Tilt-bottom Mixing Tank with Hinged Lid

Jacketed Dish-bottom Mixing Tank with Top Manway

Jacketed Conical-bottom Mixing Tank with Top Manway

Jacketed Tilt-bottom Mixing Tank with Top Manway

Jacketed Conical-bottom Mixing Tankwith Side Installed Agitation

Jacketed Conical-bottom Mixing Tank with Top Manway and Window

Jacketed mixing with homogenizer dispersion

High Shear Mixing Tank With scraper

Magnetic mixing tank with Jacketed Top Manway

Jacket electric heating mixing tank with scraper

Request A Free Quote

Have Any Questions?

+86-18626835909

+86-577-28888259

Support 24/7