jacketed mixing tank

jacketed mixing tank is a container that has a secondary wall (jacket) around it that can be used to control the temperature of the contents inside. Jacketed tanks are commonly used in the food and beverage industry because they allow for precise temperature control of liquids and other ingredients.

Jacketed mixing tank is commonly used in food and beverage production plants.

These vessels come in all shapes and sizes and can also be customized to suit your needs.

The right type of jacketed tank can help you mix, store, and control the temperature of the fluids you need to produce high-quality products.

- jacketed mixing tanks

- Stainless steel jacketed mixing tanks

- Tank Manhole

- Agitator

- Specification: 30L~50000LMaterial: SS316L or SS304

- Surface finish: inside surface is Ra0.28~0.4μm by mechanical polish. (passivation or electrologist are optional). The outside surface is Ra0.6~0.8μm with a satin finish.

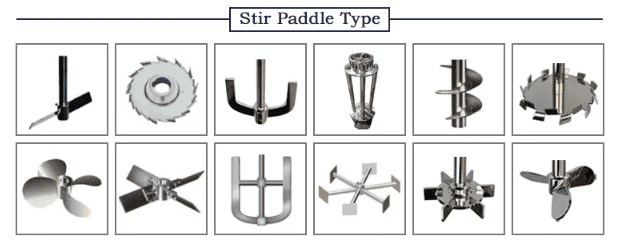

- Agitator: Top mechanical agitator (propeller, spiral, and anchor, or others)

- Pressure: ATM or pressure vessel (-0.1~1Mpa)

- Structure: Single layer vessel, a vessel with jacket, a vessel with jacket and insulation

- Jacket type: dimple jacket, full jacket, or coil jacket

- Insulation material: rock wool

- Components: vent filter, temp. Gauge, level gauge, manhole, sight glass with lamp, and cleaning ball or according to client’s detailed requirements.

- Manufacture standard for pressure vessel: ASME, PED 97/23/EC, GB150-2011

Customized to your specifications and manufactured according to the following criteria:

- Size and geometry

- Material viscosity

- Pressure requirements

- 100% sanitary interior welds.

- Ease of cleaning (CIP) for fast and efficient cleaning operations

- Mix impeller size and quantity

- Mix with a set speed or variable speed according to your requirements

Mix with impeller motion in one direction or agitating according to your requirements

Many industries use cooling/heating jacket mixing tanks. Heat exchangers can be heated or cooled, reducing reaction heat and viscosity.

Are You Looking for A Reliable Supplier of distillery equipment??

Feel free to contact us with product questions or to request support at any time; we'd be happy to assist.

Didn't find the right product or want some suggestions? Please contact us right away!

Request A Free Quote

Have Any Questions?

+86-18626835909

+86-577-28888259

Support 24/7