Producing a Flowchart of the Brewing Method

schematic of the brewing process

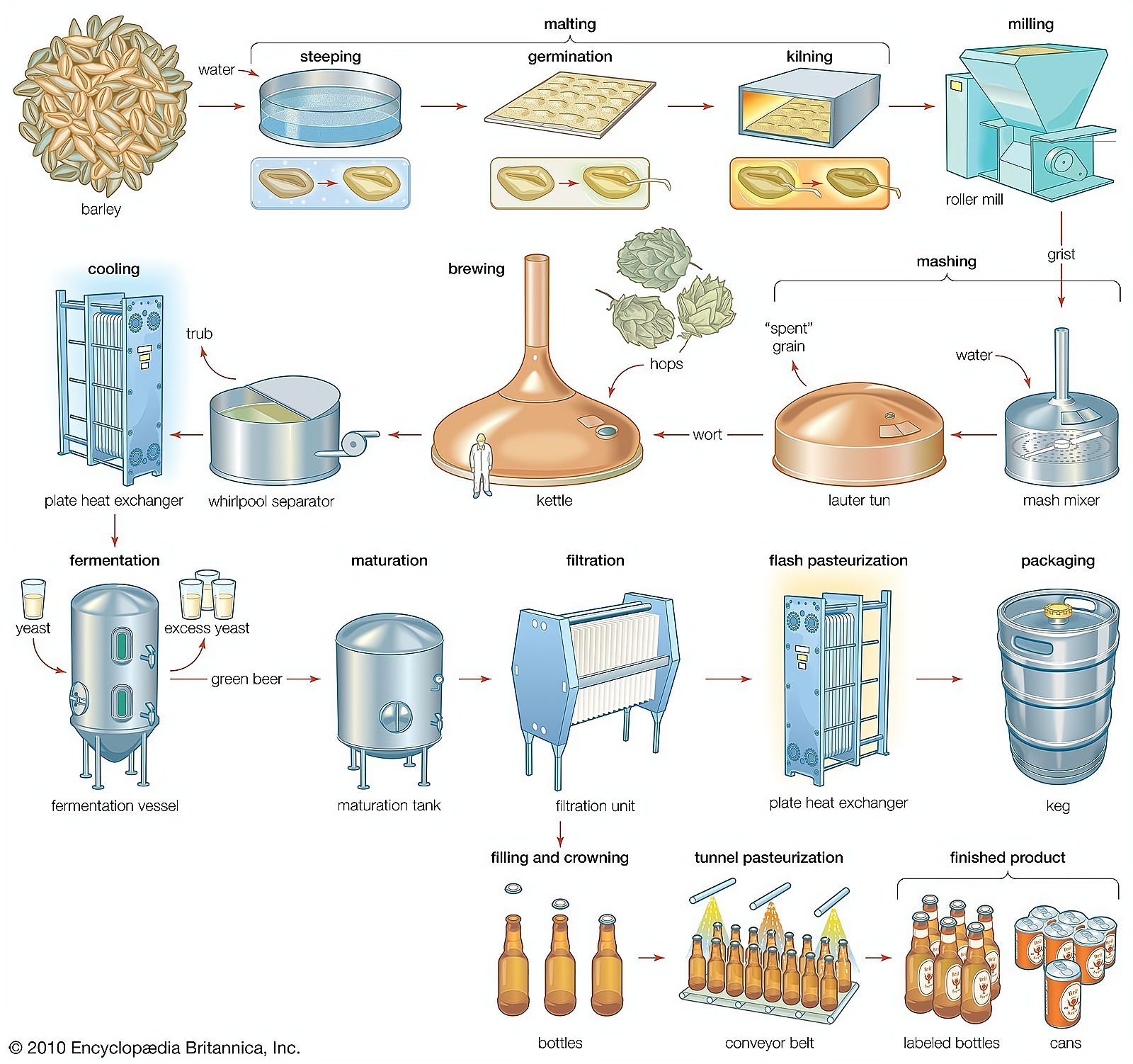

You can learn more about the steps involved in making beer by drawing a diagram of the brewing process. The diagram can also be used as a teaching aid when explaining the brewing process to pupils.

brewing process diagram

Boiling

Boiling the wort is essential in brewing because it kills any bacteria or off flavors and is also essential for keeping the water clean.

The amount of wort that evaporates from the kettle during the boil is affected by the atmospheric pressure and relative humidity. The amount of water exposed to the air also plays a role. How much water evaporates depends on several factors, including the kettle’s dimensions, the ambient temperature, and the strength of the heat source.

The wort boils for a total of 75–90 minutes. Beers with a lot of flavor and depth can be made by boiling the ingredients for longer. However, lighter-colored beers benefit from a shorter boil time.

During the wort boil, a whirlpool phase is used to filter out impurities. During this step, hop pellets are typically added. As a filter, they help keep unwanted particles out of the wort.

Sparging

Sparging is an essential part of the brewing process, and it’s a method for making the most sugar from stale grains to make alcohol. You need to know how much water to add to your mash to achieve the best results from your brew.

You may get a sense of what’s happening by measuring the specific gravity of the wort with a refractometer. It’s crucial to ensure your sparge water is at the right temperature, and you want it to be about 170 degrees Fahrenheit (or roughly 77 degrees Celsius).

To accomplish this, a sparge arm is your best bet. As a result, your grain will get a more even soaking. A suitable vessel to collect the wort is also highly recommended.

A refractometer is another helpful tool for quantifying the sparging effect. When the specific gravity reaches 1.10, you can safely stop sparging.

Extract Plus

When first getting into homebrewing, it’s recommended that you start with extract brewing because it’s simpler than all-grain brewing. It’s a fun and inexpensive way to explore a new interest.

Using an all-grain brewing method takes significantly more time, energy, and effort than malt extract. The brewing process can take up to a day, and there may also be a considerable amount of cleanup required.

The process of brewing using extract is simple and requires fewer ingredients and equipment. Most people who brew their beer at home use what they already have, and it’s a tasty and enjoyable way to get started in the brewing hobby.

Removing a portion of the wort’s water enables the extraction process, and this aids the beer in keeping its shape and lengthens its shelf life. Typically, the resulting beer has an alcohol content of 1% to 1.5%.

Fermentation

When it comes to fermentation, yeast is the key player. This process breaks down the glucose in the wort into carbon dioxide. In turn, alcohol is created. In addition, it generates enzymes that facilitate the separation of starch. It breaks down into building blocks of protein, like the branched-chain amino acids. Acetate esters and other taste chemicals are also produced. Beer’s final organoleptic character depends on these factors.

The rate of fermentation depends on a variety of things. Several factors affect the final product, including wort temperature, yeast type, and ingredient quality. Time spent in a fermenter is another factor that might alter the final product.

Brewing begins with the wort, which must first be prepared. To do this, we cool the wort and add yeast. There is no more important step than this one.

Storage

The secret to success is brewing in a container large enough to hold the wort you want to use. Stainless steel is the material of choice almost everywhere. A regular cleaning schedule is also essential. Even though using a sponge to remove the wort from the tank is recommended, this is only sometimes feasible. A well-kept brewery is a much more pleasant place to work.

The sanity of the brewing staff is directly tied to how effectively the brew system is cared for. Transferring the wort to the storage vessel before bottling is suitable for ensuring the wort is clean. A fermenter that has been adequately cleaned will produce beer of uniform quality and flavor.