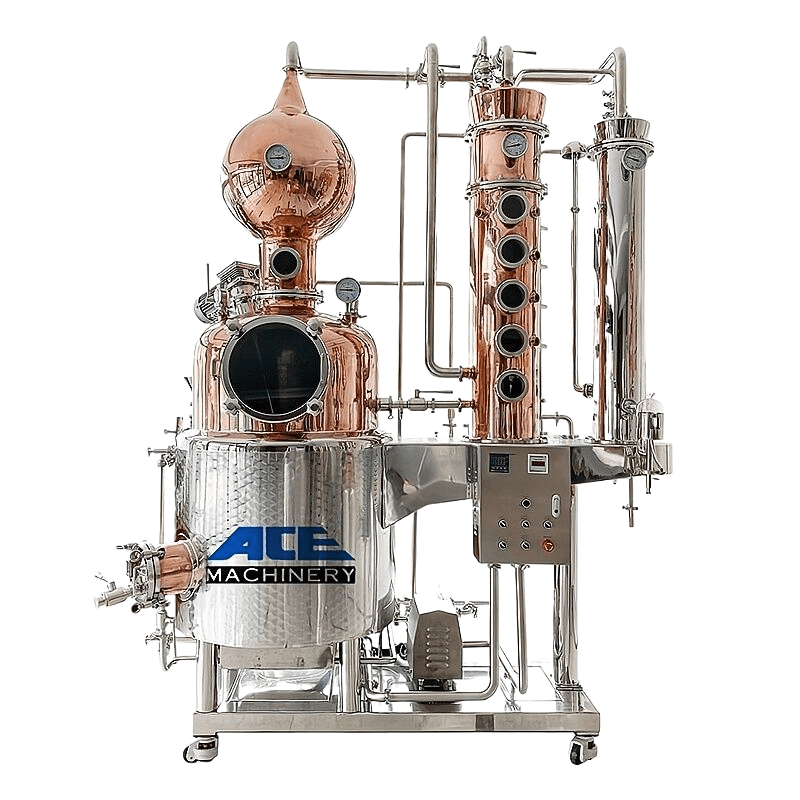

200L brandy distillation equipment

The still pot's outer shell is made of food-grade SUS304 and its inner shell is made of copper.

It is also equipped with a liquid thermometer, a pressure gauge, a thermometer probe, a safety releasing valve, a CIP cleaning ball, and drain valves.

Whether you’re looking for a distillation equipment to make your brandy or want to make a better gin or vodka, copper is the material to use. Copper is malleable, easy to clean, and can remove sulfides from distilled alcohol. It also keeps the temperature steady through the distilling process.

Our 200L Pro Series brandy still, steam-heated and jacketed, is shown. This is still ideal for making brandy, whiskey, bourbon, moonshine, vodka, and rum. With a low-pressure steam boiler, it must be heated.

Product name: 200L distillation equipment

Volume: 200L (50-5000L can be customized)

Material: SUS 304, SUS316L, copper

Thickness: inner tank 2.00-4.00 mm, pit 1.5 mm, outer shell 1.5-2.00 mm, according to customer requirements

Structure: disc top, cylinder body, cone bottom; single layer or jacket.

If there is a jacket, it has a pit jacket and PU insulation, with insulation thickness of 50.00-100.00 mm according to customer requirements.

Polishing: The inner tube is mirror polished, and the outer shell can be mirrored polished or Matt polished.

Accessories: side manhole, yeast inlet, CIP spray ball, CIP pipe, casing, sampling valve, spinning valve, pressure gauge, lifting lug, jacket inlet and outlet, outlet, outrigger bracket, adjustable foot.

distillation equipment Features

- Flexible modular system; available component combination.

- The rectification column has a small footprint, easy operation and usage, and high-quality distillate optimization.

- Using copper catalytic converter technology ensures that undesired acid, cyanide, and urethane content will be reduced.

- The distillate may be rectified and purified using our high-efficiency rectification column, resulting in alcohol concentrations of up to 96% vol. at any required purity level.

- High safety, high productivity, extended service life, low energy consumption, high quality, and affordable 360-degree cleaning CIP spray ball.

- The fine distillation bottom and the increased copper contact surface work harmoniously in this constantly changing design to guarantee that the desired taste emerges and separates from the undesirable elements.

FAQ

Will distillation equipment’s uses grow more and more in the future?

Although distillation technology has advanced quickly in recent years, there are still several issues with the process, including a lack of business and poor product quality. These issues will broadly impede the development of correcting machinery. So it’s crucial to take advantage of the chance. If you can take advantage of the chance, the distillation equipment market will have much room to grow.

Can distillation equipment firms widen their distribution networks to become more competitive?

Although distillation equipment is commonly utilized today, only some goods with a high scent or efficiency are produced. Low-level products are also frequently produced, and brand marketing needs to catch up to competitors. Expanding sales channels is a must for distillation equipment firms to increase competitiveness.

And create upscale things.

What advantages does the network provide to the market for distillation equipment?

Network marketing has increased in recent years and has many uses. It primarily resides at the network’s core, overcoming the conventional notion of the sale, increasing sales effectiveness, and successfully creating interactive communication. The transaction may be finished online, and it is convenient.

200L distillation equipment Videos

Are You Looking for A Reliable Supplier of distillery equipment??

Feel free to contact us with product questions or to request support at any time; we'd be happy to assist.

Didn't find the right product or want some suggestions? Please contact us right away!

Request A Free Quote

Have Any Questions?

+86-18626835909

+86-577-28888259

Support 24/7