1BBL Bright Tank

The 1bbl bright tank is a container for maturing and storing 1bbl beer. There is no need to separate the beer into kegs or bottles for further maturation. ace's bright tank can be used as a Brite beer tank or as a serving tank. With many built-in carbonation stones and pressure gauges, the 1bbl bright tank can also be used to carbonate beer. We can also provide you with a digital thermometer so you can check the temperature of the beer in the tank at any time.

1BBL Bright Tank Specifications

1BBL Effective volume

1.25BBL Total volume

SUS304/SUS316 stainless steel Size: 620*1200 mm

PLC Siemens or PID Schneider/ABB brand control system

0.4m2 Polishing/drawing/mirror surface/passivation with pickling

Working pressure: inner jacket 0.2MPa, 0.3 cooling jacket MPa

Test pressure: inner jacket 0.4MPa, cooling jacket 0.5MPa

1 HL = 100 liters; 1 gallon = 3.8544 liters; 1 barrel (BBL) = 117 liters

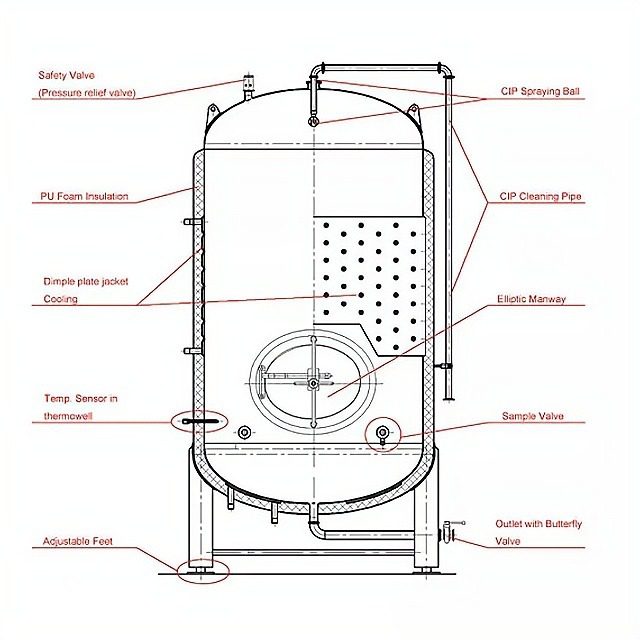

Bright tank drawing

Standard 1BBL light tank configuration

Food grade 304/316 stainless steel construction

Cooling jacket is double walled and pitted

Passivated inner surface, 2B finish

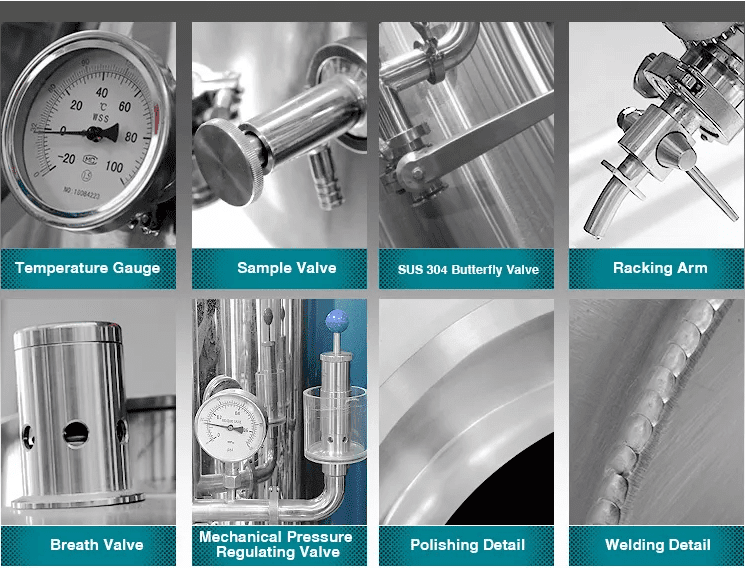

Triple-clamp sanitary sampling valve

Temperature holding bottle PT100 with sensor and 360° coverage CIP manhole spray ball

No shading / high pressure

Ice water inlet/outlet threads

Pressure reducing valve with pressure gauge

Lifting rod tank top edge

Adjustable bolts on the heavy-duty legs On the

Top of tank with a safety valve.

Carbonate rock

Liquid level indicator

Advantages of the 1BBL Bright Tank

- The fermentation tank has lifting lugs for easy lifting of the equipment into place.

- The use of rotating elbows and racking teams to transport beer is both convenient and flexible.

- For more precise machining accuracy, oval shields are added to the joints of the legs, lower cone refrigerant inlet pipe, and lower cone outer package.

- All tanks have adjustment bolts to ensure proper alignment and leveling.

- The fixture is installed at the connection of the spout and tank bottom, which can be rotated at will to facilitate customer operation.

- Bright tank bottoms are made from finished products to ensure a beautiful, strong and durable tank.

- All Bright tanks have carbon stones for CO2.

- It uses easy-to-clean shadowless manholes. The top manhole can be designed to suit the customer’s fermentation process and beer brewing.

- The volume of the top head is not included in the total volume of the top space.

- The cone is designed with cooling jacket at the top and bottom with sufficient cooling area.

- With safety device and positive and negative pressure opening function.

- The 60 degree cone angle is ideal for yeast excretion.

- The fermentation tank is equipped with a special ladder for easy access.

- Two types of cooling tanks are available: exchange type and copper tube cooling tanks.

- Various cooling solutions designed according to country and brewing characteristics.

Bright tank Videos

Are You Looking for A Reliable Supplier of distillery equipment??

Feel free to contact us with product questions or to request support at any time; we'd be happy to assist.

Didn't find the right product or want some suggestions? Please contact us right away!

Request A Free Quote

Have Any Questions?

+86-18626835909

+86-577-28888259

Support 24/7